Oil & Gas 2

The Case

Before commissioning a particular umbilical and chemical combination, it is essential to carry out tests for compatibility by subjecting hose samples to elevated pressures and temperatures, while exposing them to chemical fluids to be carried in service. These tests can run for several weeks or months, during which time the integrity of the umbilical hose liner is monitored at regular intervals. Key properties of the hose material samples are measured periodically throughout the tests to determine whether any deterioration has occurred as a result of chemical attack or physical degradation.

The Approach

This approach combined three instrumental techniques providing a powerful analytical tool to undertake this type of work.

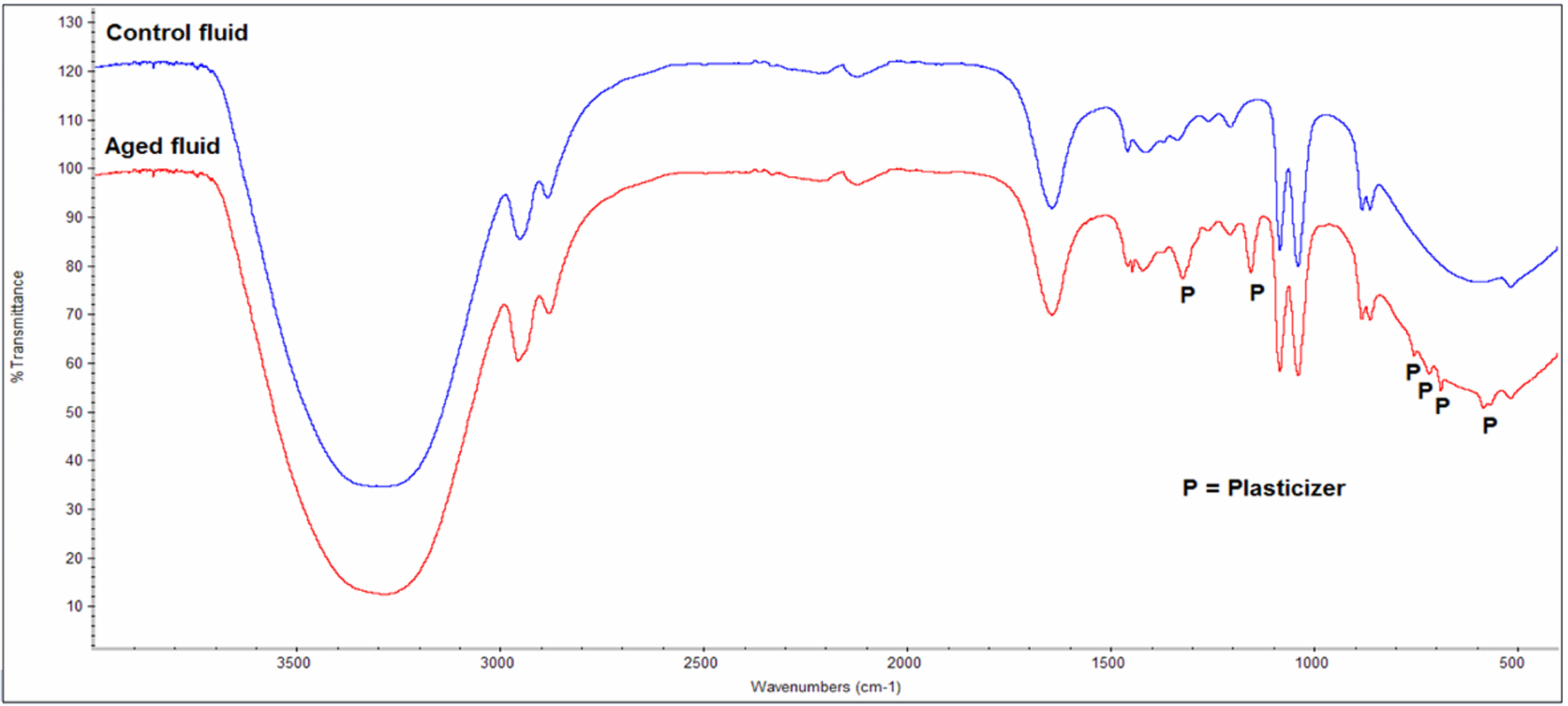

Fourier Transform Infrared (FTIR) Spectroscopy to determine if the umbilical liner has been chemically attacked by the test fluid (e.g. leaching of the polymer material plasticizer).

Infrared spectra of the control and aged chemical fluids are recorded using an FTIR spectrometer, fitted with a diamond attenuated total reflectance (DATR) accessory. Comparison of the two IR spectra allows the qualitative detection of any additional contaminants (plasticizer) in the aged fluid which have been leached from the umbilical liner with as little as 1% w/v of a contaminant being detectable.

Comparison of IR Spectra

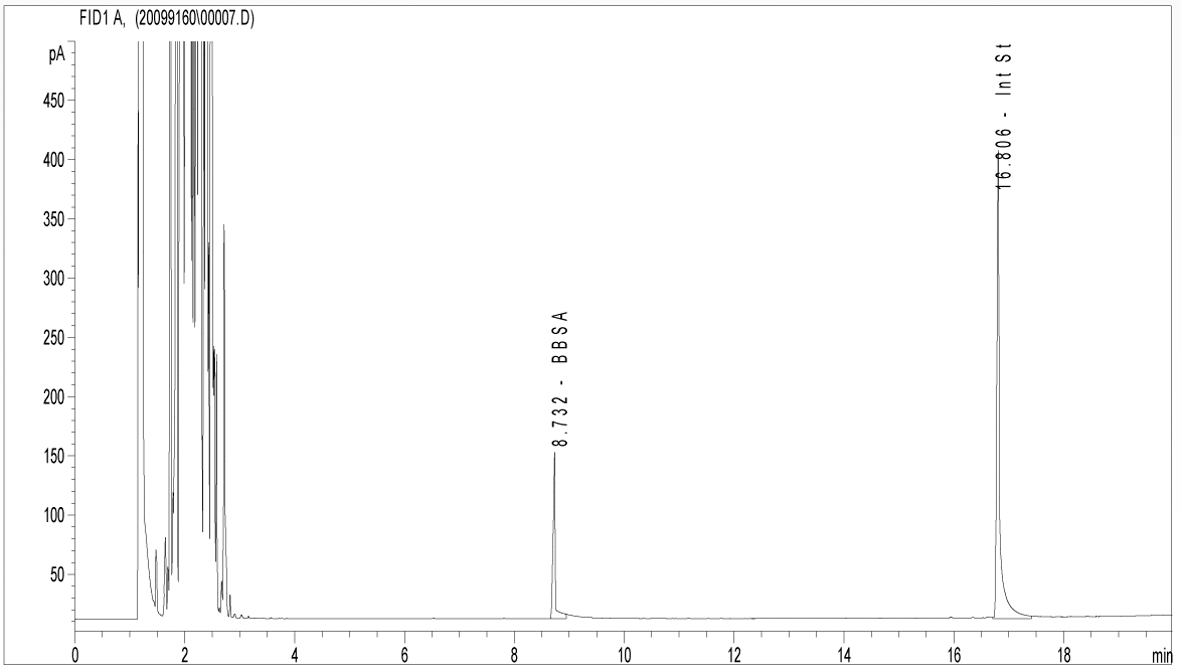

Gas Chromatography (GC) to quantify the leached plasticizer in the test chemical. The plasticizer (in this case Butylbenzene sulphomide, BBSA) is quantified with reference to an added internal standard. This allows the client to gauge if the concentration is within acceptable limits such that the umbilical/chemical combination can be used in service or if not, allows the selection of an appropriate alternative combination at the outset, avoiding costly in-service failure.

BBSA plastisizer peak and internal standard peak.

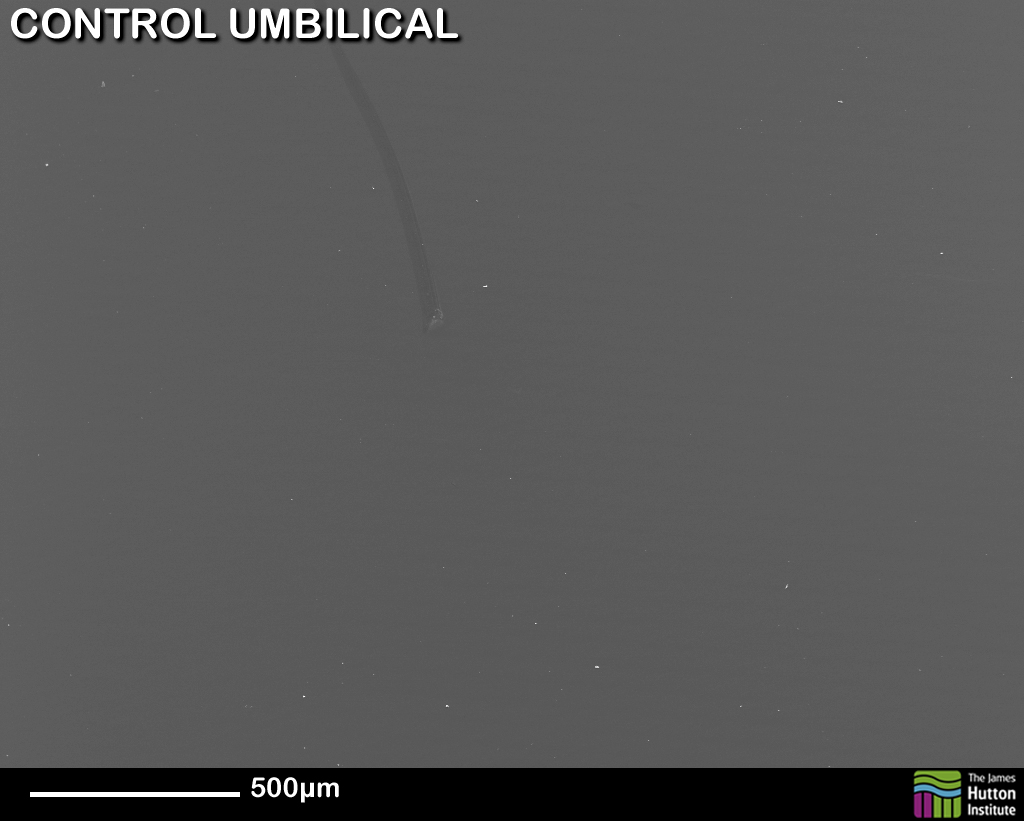

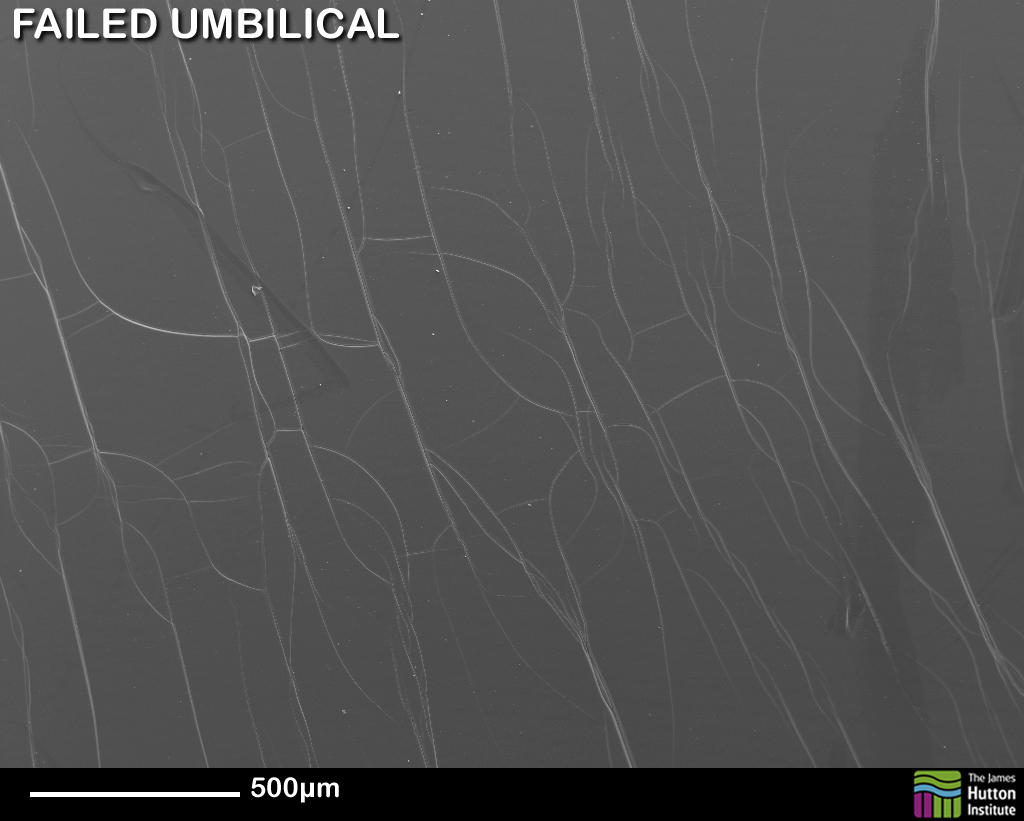

Scanning Electron Microscopy (SEM) to ascertain the physical condition of the liner (e.g. the presence of surface micro-cracks). Following the failure of an umbilical liner during testing, SEM images are produced to compare the inner surface of the failed liner with an untested (control) specimen. Both the control and the failed liners are sampled using a surgical blade, first cutting along the longitudinal axis of the umbilical, then transversely to try and minimise the stress to the material whilst cutting.

The resultant high magnification SEM images can provide evidence of any physical/chemical degradation of the umbilical liner.

The Cost-Saving Outcome

The combination of these techniques provides a powerful and effective three-pronged approach for testing the compatibility of umbilical liners and chemical fluids in relation to the potential for chemical and physical degradation of the liners during prolonged injection.

The chemical and physical analysis of liners and production chemical following controlled aging tests provides crucial and definitive information for the client in advance of any chemical deployment to determine material compatibility and avoid potentially costly umbilical liner failure during service.